Inks that don't dry out / Infinity Inks

-

Forum Statistics

355.6k

Total Topics4.6m

Total Posts -

Member Statistics

128,468

Total Members18,857

Most OnlineNewest Member

AnitaPH1

Joined -

Images

-

Albums

-

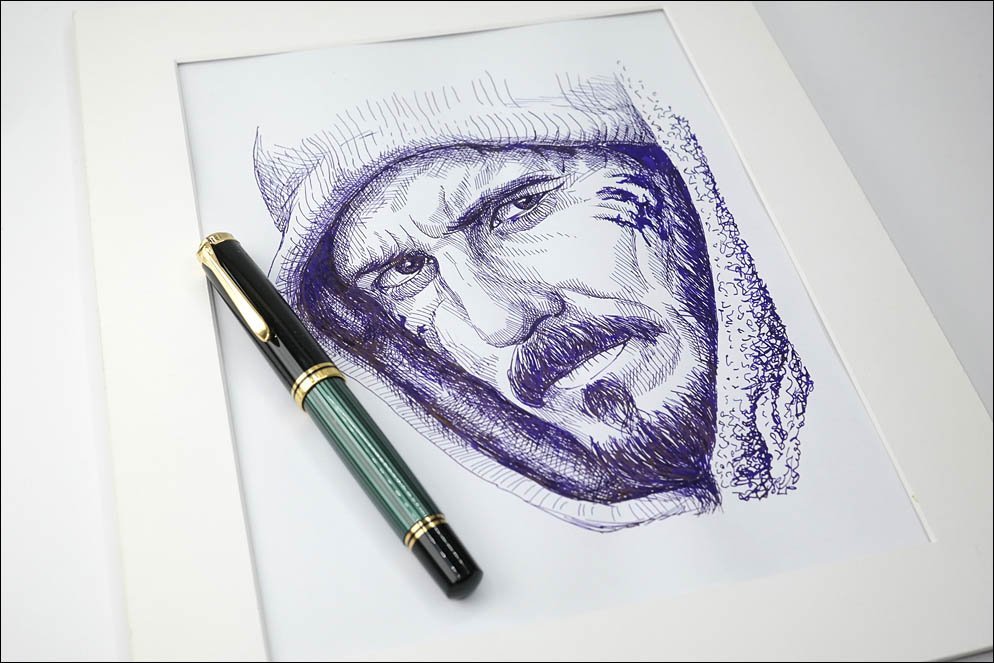

Andrew Lensky Arts

- By Andrew_L,

- 1

- 21

- 48

-

USG 11

- By USG,

- 0

- 0

- 12

-

Pelikan Xuan Wu (2001) - Asia Limited Edition

- By tacitus,

- 0

- 0

- 15

-

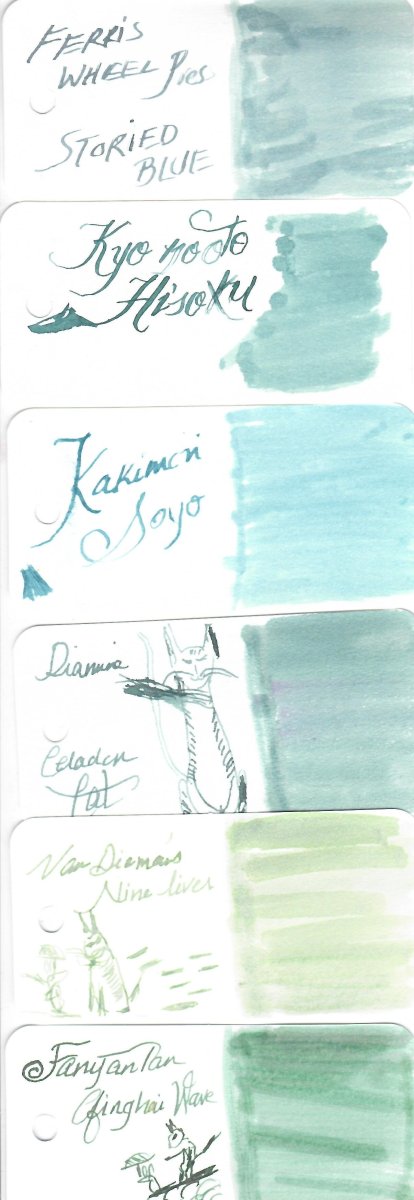

00-Feb-March-April2025

- By yazeh,

- 0

- 0

- 88

-

Misfit’s 3rd Album for pens, paper, ink

- By Misfit,

- 13

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

desaturated.thumb.gif.5cb70ef1e977aa313d11eea3616aba7d.gif)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now