How to remove a Parker 75 section ring?

-

Forum Statistics

355.2k

Total Topics4.6m

Total Posts -

Member Statistics

128,245

Total Members18,857

Most OnlineNewest Member

cranefly

Joined -

Images

-

Albums

-

4posts

- By Tashi_Tsering,

- 0

- 0

- 72

-

customization Of Ranga

- By Harish N V,

- 0

- 0

- 3

-

USG 8

- By USG,

- 0

- 0

- 80

-

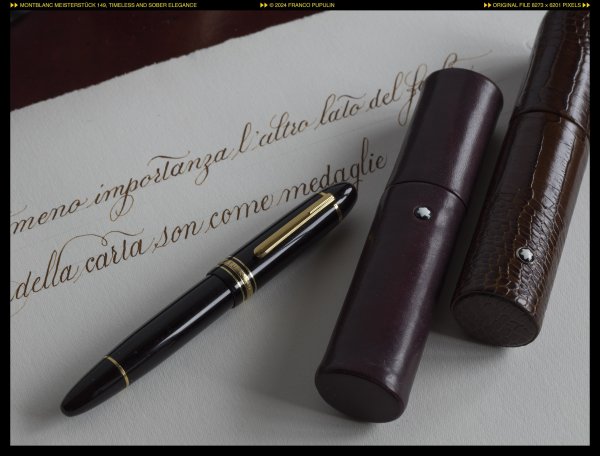

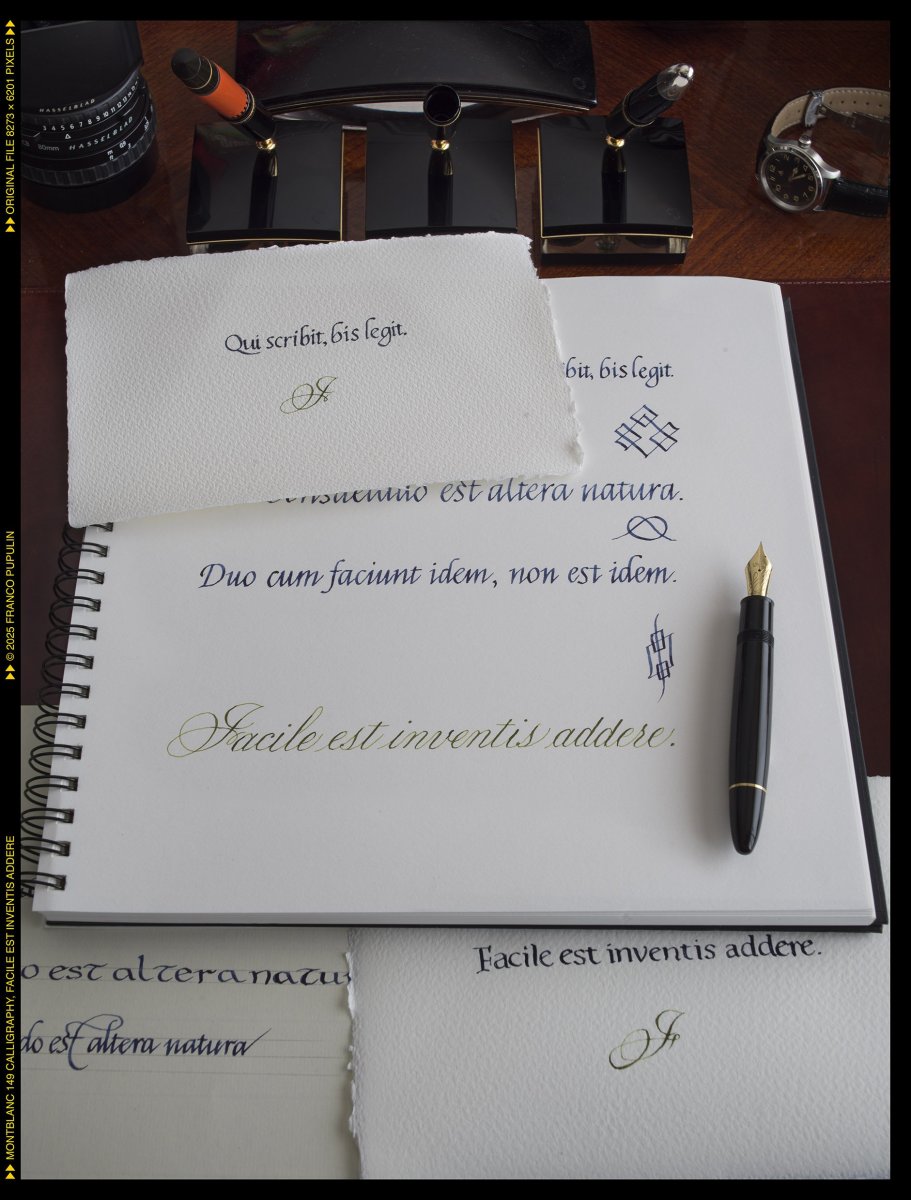

Icones Pupulinianae VI

- By fpupulin,

- 0

- 0

- 11

-

Image for posting by Number99-Ⅱ

- By Number99,

- 0

- 0

- 41

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

.thumb.jpg.331e554113c33fb39d5bf3233878978a.jpg)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now