Search the Community

Showing results for tags 'nib'.

-

Dropping the pen nib few centimeters high

penmaster6969 posted a topic in Fountain & Dip Pens - First Stop

Hi. I was writing and holding my 823. It slip out of my hand and fall onto the surface of book in table top (the height is about 3 in or just few centimeters high). Do you think the nib was damaged or misaligned? -

Scraping the nib against mouth of ink bottle after filling

penmaster6969 posted a topic in Fountain & Dip Pens - First Stop

How do you people remove the excess ink in the nib after filling your pen? I usually hold the feed against the mouth of ink bottle and scrape the excess ink using its edge and i repeat this step with the surface of the nib, and then I wipe it with microfiber cloth. Do you think scraping the nib against mouth of ink bottle damages it? or i'd be fine? What also do you do to remove the excess ink. Thank you. -

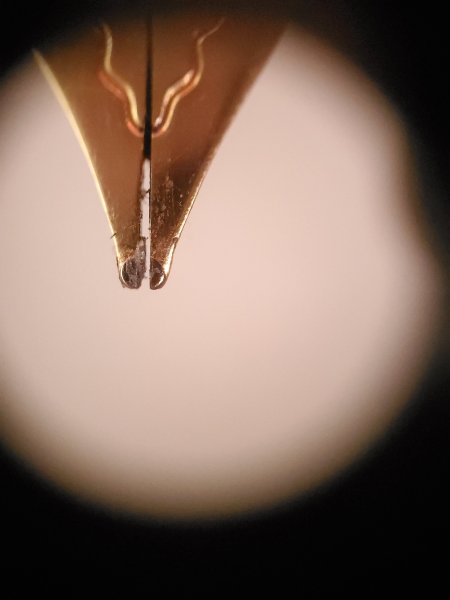

I've seen some people dropped their pen nib first, with the nib pointing down. So, does dropping the pen with nib first but on its side damages it? I was holding the pen in writing position (45°, triangular grip), then the pen slipped out of my hand (about 1" [inch] high). The nib fell onto the book laterally (on its side). This is my GRAIL pen, so I am quite emotional to determine if there's some damage--hence, I'm am not sure if the writing of the pen change--I dont have a loupe to check it out. But as far as I evaluation, there is no remarkable changes in writing of the pen. So do you think I should send the pen to a nibmeister or not? Thank you. Here are some pictures I took:

-

Increasingly, my Duofold is dry and hard to get started. Considering it’s a Broad nib, I’m wondering what’s going wrong. What would you suggest?

-

Greetings! I just got my first Pelikan, an M150 old style. I noticed that the nib seems to be too deep into the section. The M is barely visible. I tried to unscrew the nib, but impossible. I tried heating with hairdryer, ultrasonic cleaning, and 5-56 lubricant. Soaked in water overnight. But the nib is really stuck, even using force and rubber gloves. Perhaps I should leave the nib permanently fixed. The pen writes really well. But what might have happened to this pen?

-

Hello I have a montblanc 146 from the 50s but the nib is broken, so I’m wondering if it’s something that can be repaired? Thanks!

- 14 replies

-

- repair help

- repair

-

(and 1 more)

Tagged with:

-

Visconti Homo Saipen and the Nibs PSA

The_Beginner posted a topic in Fountain & Dip Pens - First Stop

Hello FPN, Long time no see from one of your resident FP scientists, I come today with a delightful discovery. I have recently discovered that the Bexley 14k nib is a almost 1 to 1 perfect drop in fit to the Visconti nib! I have included some photos but as some of us not all but some have gotten a bum nib on the V HS i just wanted to inform you guys on this cheaper and lil bit more cost effective way possibly for a nib swap. I bring this only up because this pen and its original nib have always given me grief and i wouldve sent to a nib meister but oddly i always had that nagging weird feeling it would be lost somehow in the mail. So thankfully after testing many a nib this was the best result a 99% match with no issues whatsoever rn! Thank you for your time the beginner! -

Hello everyone, I am very much new to FPN and posted this originally in Of Nibs and Tines. I then discovered this part of FPN and thought it might be a better fit for this question (I hope it is not against any guidlines). Recently I fell in love with the Parker 45 and its huge range of models and nibs. I am particularly fond of the oblique nibs and I acquired a few of them. I hope some of the Parker 45 experts can help me The nib sizes seem to vary a bit. I have two 14k "O" nibs. These are supposed to be extra broad oblique nibs. The first one I got is made in England and in a Parker 45 Insignia (no tassie, mid 1970s) It is akin to a oblique italic. I would also not call it a double broad yet it is quite broad. The second one is an American-made, in a Flighter CT (black tassie, 1964-1969). This one is very broad and has a lot more tipping. It is way broader than the first nib and the imprint on the collar is closer to a "0" insted of the "O" on the first one. I attached pictures. The English one is on the right, the American on the left. Additionally, I also have a 14k "Z" nib (made in England) that is supposed to be a broad oblique. It is smaller than the American O nib, so that checks out. My freshly acquired "R" nib (14k, made in USA), supposedly an medium oblique, appears broader than the Z. The third picture shows the R - Z - English O - American O (left to right) Do the American Parker 45 nibs run wider? Or did the way Parker ground their nibs change during the decades-long run of the 45? Or is it simply variation that has to expected of these nibs? I know that nibs can be changed easily and so it is possible to have mismatched nibs and collars. However, I find it unlikely to have so much mismatching going on. Do any of you have similar experiences or know anything about it? Thanks in advance

- 5 replies

-

- parker 45

- parker 45 nib

-

(and 2 more)

Tagged with:

-

Hi everyone, I hope everyone is having great holidays. I am french speaking person so I hope my english will be up to the task of explaining the whole story. We were cleaning the house at my family-in-law's and I found a fountain pen in a box with tens of your everyday plastic pens (bic and no-brand). Among the fountain pens, I found one which caught my eyes. After a couple of hours of research, I identified it for a Parker 35 Silver plated with guirlande patterns. My father in law seems to remember that this pen belonged to his mother and offered it to me. I like pens (I own a Namiki myself) and this Parker 35 looks great and feels great in my hand, I'd be glad to use it. The problem is the nib which is labeled "Parker 750" at the front and "3" at the back. I tried with a new ink cartrigde and it is scratching the paper so hard, it's impossible to write. Do you know if this kind of nib is easily straightened / repaired ? Is it possible to replace the nib ? I think of it as a last resort... Do you know if this pen can be used with a converter ? It was stored with a parker long ink cartridge but I would prefer a converter if compatible. Has anyone some tips to clean / polish the silver plating without damaging it ? Thanks for reading and happy holidays !

-

It is common among the community to say that gold nibs are not better than steel nibs. I disagree since most gold nibs are hand polished and tested one by one while steel nibs are mass produced in automated processes. So, in order for a steel nib to compete against a gold nib, it would need to be hand polished, hand finished and hand tested. Currently the only steel nibs that I am aware that are hand made are the Kaweco Premium Steel nibs (which cost $50 USD), , the steel nib of a Hero 40 years reform and opening special edition 英雄钢笔1978改革开放40 and Edison Pens. Maybe Faber-Castell steel nibs are also hand polished given their quality. But most steel nibs are not: Pelikan, Aurora, Lamy, etc. So, the question is what brands do you know that offer hand polished, hand finished steel nibs? Since today it was a cleaning day, I share a picture of a clogged feed and how I left it.

-

I have two 146’s. One pen is older and has the nib holes 180 degrees apart and the other is a more modern Bordeaux 146 with nib holes offset. I have tools for the older 146 but not for the newer nib hole 146’s. I really did not want to pay $40 $50 dollars for another tool. I read that the MAJOHN P136 was the size of a 146 and saw they had a take down tool. Per the instructions it looked like it would work on the nib assembly of a newer 146 Montblanc. So I decided to try an experiment and purchased this tool for $10 and free shipping. I purchased it Jan 30 and it arrived to me in Texas on Saturday Feb 11 Well it worked like a charm on the piston and more importantly on the nib assembly. I hate adding eBay links because in time they are no good for future searches but I thought I had to tell y’all to take advantage of this while you can. Someone else sells the same tools but it’s listed for “Montblanc use” and they want $20 for the tool and $20 for shipping. Hope this helps someone, it did me. Cheers,Ozzy https://www.ebay.com/itm/394315658418?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=OSSpmWOnTcO&sssrc=2047675&ssuid=bZUb89HITrK&var=662832818694&widget_ver=artemis&media=COPY

- 16 replies

-

I've read that Lamy has released special Hanzi nibs in Asia. They seem to be on the "architect" side to aid with Chinese or Japanese writing. I can't write Chinese but I'm curious. Anyone used one? https://www.instagram.com/p/CYc46c2vLFN/ https://www.instagram.com/p/CYfVKvQvUKn/ But since when is there a matte red Safari? 🤔

-

From the album: Mercian’s pens

A photo to show the 12-rayed sun logo on the gold-plated steel nib of my Geha 700 Schulfüller from the late 1950s. I have uploaded this photo to see if anyone else has a Geha nib with the same logo on it - I wonder whether the number of ‘rays’ on the disk of the sun may indicate anything e.g. nib size, shape, or degree of hardness. This nib is an ‘FK’ - an ‘F’ nib with a ‘kugel’ (ball) tipping, as opposed to the flat, ‘cursive-italic’ tipping shape of many German pens of the 1950s. The gold plating has nearly all worn off this nib now, but (in 2024) the nib still works beautifully. This nib is slightly ‘springy’, or ‘bouncy’. It is by no means a ‘flex’ nib; being slightly less ‘bouncy’ than is the steel ‘F’ nib on my Pelikan M205 from 2012, or the 14k gold ‘M’ nib in my Pelikan M400 from the 1990s (1991-97).© Mercian

- 0 B

- x

-

From the album: Mercian’s pens

A photo of the gold-plated steel ‘FK’ nib on my Geha 700 Schulfüller from the late 1950s. Almost all of the gold plating has worn off the nib, but (in 2024) it still works beautifully. It is slightly ‘bouncy’ or ‘springy’; not by any means a ‘flex’ nib. It is slightly less ‘bouncy’ than is the steel ‘F’ nib on my Pelikan M205 from 2012, or the 14k gold ‘M’ nib on my 1990s (between 1991 & 1997) Pelikan M400.© Mercian

- 0 B

- x

-

Advice on vintage Onoto nib sizes and interchangeability?

velox brunneis vulpes posted a topic in Fountain & Dip Pens - First Stop

Dear fellow FPNers, I have recently acquired 2 vintage Onoto plunger fillers, a model 3000 with a No.3/ST nib, and a model 6000 with a No.3 nib. Could someone please let me know if the nibs are interchangeable? And what does the "ST" on the No 3/ST stand for? I look forward to your feedback Thanks in advance! Best, J- 1 reply

-

- onoto

- onoto de la rue

-

(and 4 more)

Tagged with:

-

Parker Vector writes like a dream, but rude awakening when neglected.

T.D. Rabbit posted a topic in Of Nibs & Tines

Apologies for the cryptic title. I wanted to make it funny. Not sure where to post this exactly, but my problem probably has something to do with the nib, so. Okay, so I have a Parker Vector, bought in India- To be sold in India and Nepal only- and while I had issues starting out with it (It was my first fountain pen in years, and indeed, my first good fountain pen) and left it for a year or two (Edit: I cleaned it out before storing it away, and cleaned it again, thoroughly, before starting to use it more recently. So, probably not a dry ink issue.)... It started writing pretty well recently after I followed some recommendations I found around here and other places on the great wide internet: - Lightly pressing down the pen nib to... open up the tines somewhat, maybe? It was being too dry, hence. But I did this only once with this pen, compared to the relative torture I inflicted on my platinum preppy- That's another story! -Strokes from side to side. This really helped, somehow. -Using better paper- Okay, that one was on me. I was using paper smoother than my brain, and pretty thin. Once I moved on to using only the paper that 'felt good', my experience was bettered considerably. However. Recently, I've been having a problem. I write with the pen, and it writes very well, but then I have to leave it open for maybe half a minute listening to a professor, and when I get back to writing, I have to run it about a bit before it starts writing again (It gets dry-ish.)- Not ideal in fast-paced classes! I love this pen, and I want to keep using it, but I might have to keep this aside for when I have longer, personal writing sessions... And I don't want to do that. TL;DR: Parker vector writes well, but when left open for even 30 seconds, has a dry start. A very dry start. I have attached pictures of my nib. Further, this may have something to do with my, I suspect somewhat diseased, convertor? It's very old, it's very cheap, and the ink doesn't really stay above the piston all the time- There's always a thin layer left below it. Have also attached a picture of the convertor. Further, there are often bubbles above the ink when the convertor is partially filled, giving it the appearance of being fully filled. I fill the converter through the nib, dipping it in the inkpot. As for the ink I use, Parker Quink Black, to be sold in India and Nepal only, 100rs or 1.2 dollars for 30 ml. The pen lays down a (as per me, though I'm certainly no authority) decently wet line- I love watching how it dries. Time slows down. That's about it. Thank you for reading through my slightly convoluted style of writing!- 26 replies

-

I can't deal with dry nibs in PenBBS 456

PaJaC posted a topic in China, Korea and Others (Far East, Asia)

Hello, PenBBS has been in my drawer for several years. This pen has been useless since I got it because the original nib didn't feel comfortable to me and all the others felt rough to me. I had a problem with the Bock nib, Kaweco, JoWo and none of them were up to the task. I even started buying nib products on AliExpress, but none of them satisfied me. All nibs scrape when stroked upwards and forwards, making them extremely interruptive and irritating. I started to wonder if the reason might lie elsewhere, for example in the feeder and their construction? How to deal with this? edit: The JoWo nib works well with the Asvine V126, is it the feeder that is to blame? -

Hi, Got this pen today with a splayed nib that I'm trying to fix. It had what seemed some kind of crystal (it seemed clear, glass-like) stuck between the tines. After a bit of coaxing with a brass shim, I was able to remove most of it: And after a bit more, I was finally able to remove it completely. Whatever that thing was, it was as big as the space between the tines. Closing the tines has been quite a challenge and I'm stuck at this point after trying a few things, such as crossing the tines over and pressing them to overlap with my nails and then lying the nib on one side on a piece of hardwood, crossing over the tines and pressing with another piece of wood. This is as much as I've been able to close these darn tines: Any ideas? Thanks! Alex

- 2 replies

-

- s.t. dupont

- dupont

-

(and 3 more)

Tagged with:

-

Hello, I have a Sheaffer Touchdown, no dot, steel F1 nib. I resaced, changed out the gasket, used the ultra sonic cleaner multiple times to clean the nib unit. I have gotten it to the point it draws ink into the Sac and writes for a time but then dries up. My question is, can I take the nib unit apart even further to clean it better. It looks like it might be 3 pieces but I don't want to damage it if it doesn't, isn't made to come apart any further. If it does come apart is it pretty much a knockout block or does it somehow screw apart? Pictures attached

-

-

- s.t. dupont

- dupont

-

(and 3 more)

Tagged with:

-

-

- s.t. dupont

- dupont

-

(and 3 more)

Tagged with:

-

Hi Everyone, I always use fpnibs.com as my source for JoWo nibs which they custom grind to whatever I want, but they don't offer Bock nibs. Is there anyone out that that not only sells Bock nibs but will also custom grind them for you? Thanks!

-

nib swapping Swapping a regular 149 nib of a limited edition for a flex nib

AYChopp posted a topic in Montblanc

Hi I recently bought a used montblanc limited edition (4810 pieces) 149 by andree putman, which is basically a classic 149 with a special case, I sent it to get serviced. I contacted My Jewlery Repair (montblanc's authorized repair) if i can swap the nib of a regular 149 to the calligraphy flex nib & they said they could. My question is, since its a limited edition set will I totally ruin the pen's value if i would eventually sell it or it will upgrade the pen/set? I've attached stock images of the set, Thank You- 10 replies

-

Hi, I have just received a Lamy Lx Palladium (I got on sale). I have noticed a couple of mishaps. Firstly, I noticed that there is a loose bottom finial- creating a rattling sound. I was able to use my finger to tighten it (in comparison to another one, it is not fully tightened- as seen in the photo by referencing the ‘Germany’ imprinting). However, it came loose again. Since tightening it again, it hasn’t. Is there any way that I can fix this, to prevent it loosening long term? I believe there is a hex thread in the bottom finial? A question about the nib. I noticed a grey streak on the right tine. I originally thought that it must be some sort of factory residue. I cleaned it and inked it up, however, have realised that it is still there. Could this be a spot on the nib where PVD coating is missing? Input on this would be great. And finally, a question about the feed. When capped, the feed remains black, though when uncapped, it fades to a greyish white colour. Is this normal, as I haven’t been able to find any information on this? Not sure if any of these issues or questions have to do with a slight problem I ran into. When loading a cartridge into my pen, after cleaning with a bulb syringe (with basically distilled water), and drying off, the ink just would not flow to the nib properly, as only faint grey lines came out (even after writing for a while). I tried everything to promote the ink to saturate the feed, including putting the pen upside down, gently squeezing the cartridge and writing with it. When cleaning it out, a faint pink colour came out? Anyway, I have since combatted this by using bottled ink (Pilot Iroshizuku), so as to saturate the nib and feed initially, and since I haven’t had any flow issues. Thank you in advance!

-

Hi FPN, I have a Lamy Lx and have noticed that the nib <M> is particularly scratchy, and I am a beginner and have had it for just 4 days. In comparison to another Lx, mine is really scratchy to the point where it picks up fibres on the tip of the nib, and feels like it is dragging along the paper on some strokes (it sounds like a pencil, very much so! I notice that a downwards, upwards and right to left strokes are alright, but a left to right stroke is very scratchy. It is also scratchy for a left to right diagonal stroke. This leads me to believed that it is a misaligned nib, though I don’t know how to fix that (and what the left to right stroke being scratchy means [i.e, left tine backwards, towards, etc.] Another thing to note is that when comparing mine to another Lx, the space in between the tines on mine is smaller than that of the other one. I have sent Lamy a support message, I hope that they respond. Is it worth trying to fix it myself, as it will end my warranty (I believe). Perhaps the warranty will allow me to get a completely new nib (pen can’t be returned as it was a sale item)? Any advice on this would be greatly appreciated!

- 1 reply

-

- fountain pen

- nib

- (and 4 more)